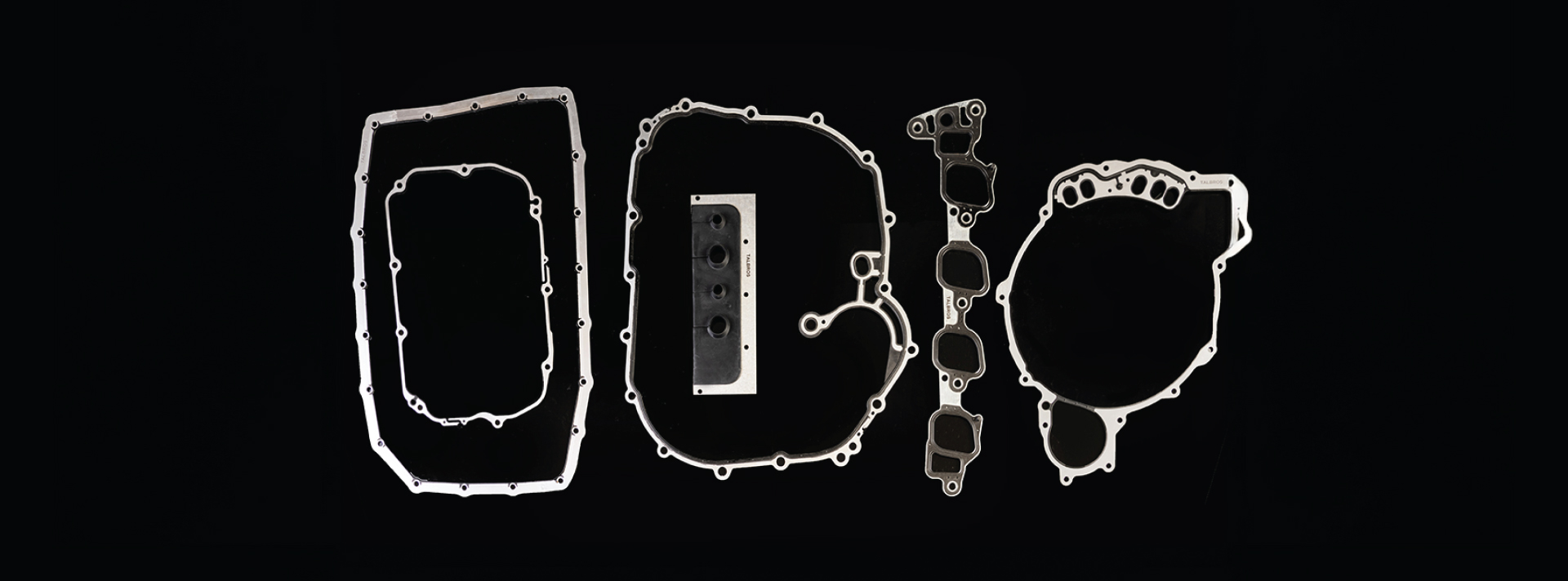

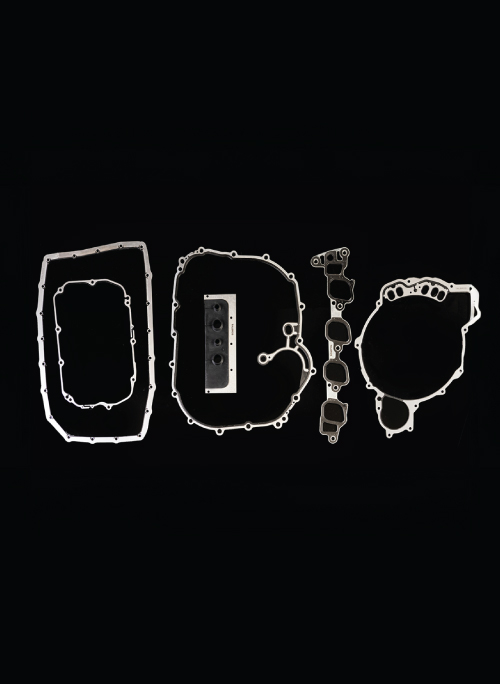

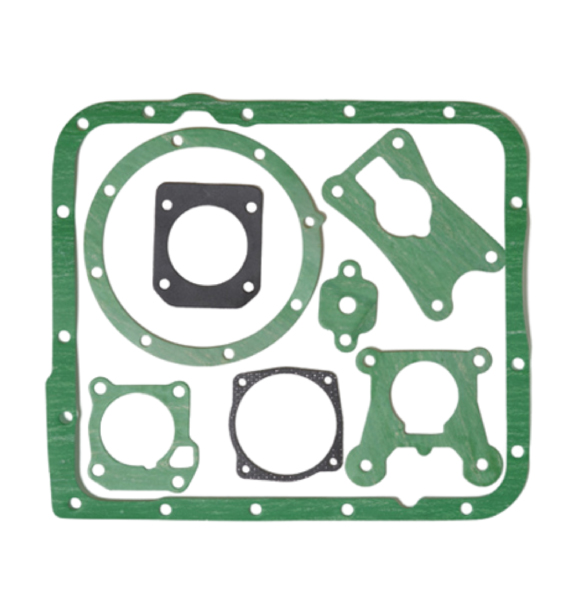

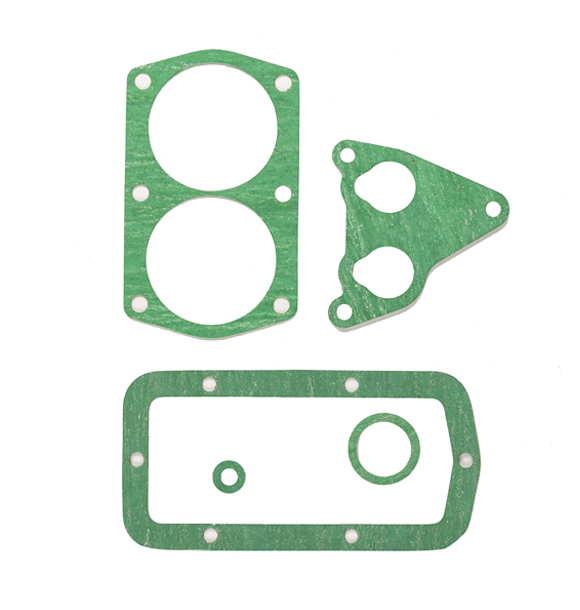

Non-Asbestos Gaskets

Non-asbestos gaskets are sealing components made from materials other than asbestos. These gaskets are designed to provide effective sealing in various applications while eliminating the health risks associated with asbestos exposure.

Material Composition

Non-asbestos gaskets can be made from a variety of materials, including:

- Fiber Materials: Commonly used fibers include:

- Aramid Fiber: Known for high strength and resistance to heat and chemicals.

- Carbon Fiber: Offers high stiffness and strength at elevated temperatures.

- Glass Fiber: Provides good thermal stability and chemical resistance.

- Elastomers: Commonly used fibers include:

- Nitrile (NBR): Suitable for oil and fuel applications.

- EPDM: Excellent for water and steam applications.

- Silicone: Ideal for high-temperature environments.

- Graphite: Often used in high-temperature and high-pressure applications for its excellent sealing properties.

- Composite Materials: These gaskets may combine fibers and elastomers to enhance performance characteristics.

Performance Characteristics

- Temperature RangeNon-asbestos gaskets can typically withstand temperatures from -40°C to +300°C (or higher, depending on the specific material).

- Pressure RangeDesigned to handle various pressure ranges, depending on the application and material composition.

- Chemical ResistanceMany non-asbestos materials offer excellent resistance to oils, fuels, acids, and solvents.

Contact Us

×