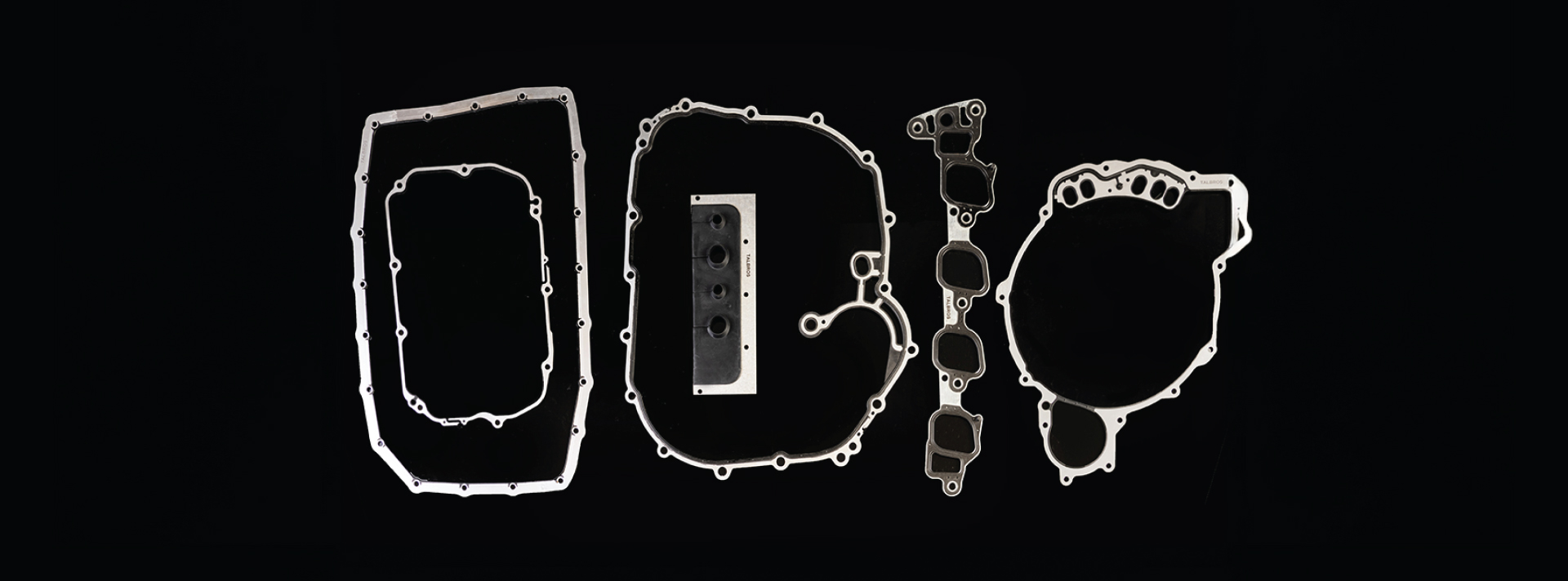

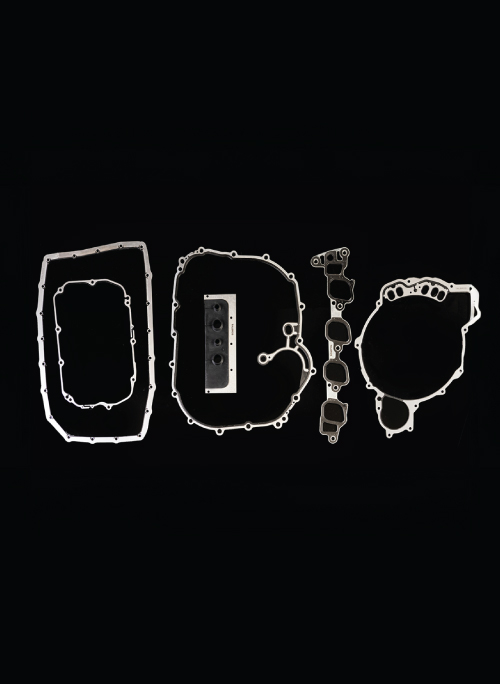

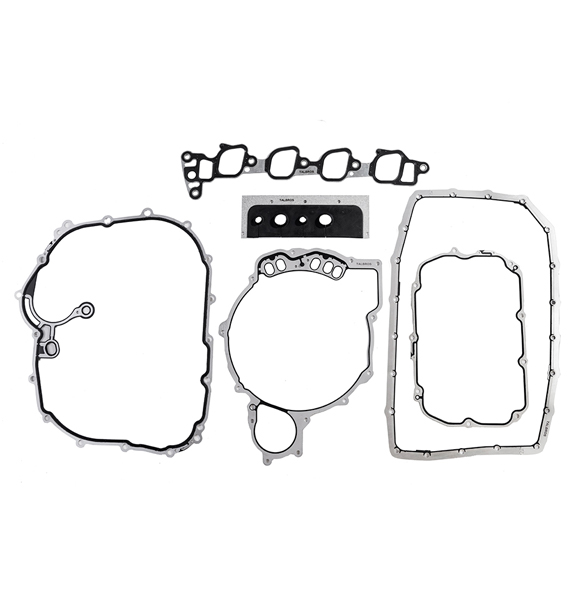

Rubber-metal Carrier Gaskets

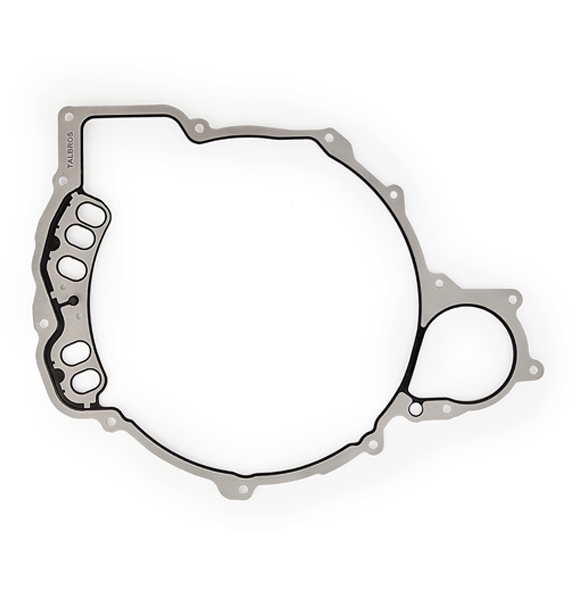

Rubber-metal carrier gaskets, often called rubber metal gasket solutions, are specially designed sealing components used in a wide range of industrial applications. They combine a flexible rubber sealing layer with a strong metal carrier. The rubber ensures a tight and effective seal, while the metal provides strength, shape stability, and long-lasting support. This combination makes them reliable and durable for demanding operating conditions.

Composition

- Rubber Component: Typically made from elastomers such as: Nitrile, AEM, HT-ACM, FKM, HNBR and Silicone.

- Metal Carrier: Usually constructed from:

- Steel: Provides strength and durability, suitable for high-pressure applications.

- Aluminium: Lightweight with good corrosion resistance, often used in lower pressure or temperature applications.

Design Features

- Profile: Available in various shapes (flat, raised, etc.) depending on the application requirements.

- Bonding: The rubber is bonded to the metal carrier using adhesives or vulcanization, ensuring a strong, leak-proof connection.

- Custom Sizes: Gaskets can be manufactured to fit specific dimensions and configurations based on application needs.

Performance Characteristics

-

- Temperature Range

- Nitrile: -30°C to +108°C

- EPDM: -40°C to +120°C.

- AEM: -40 C to +175 C

- Fluorocarbon: -20°C to +200°C

- Silicone: -60 C to + 300 C

- EPDM: -40°C to +120°C.

- Pressure Rating: Typically rated for applications ranging from low to high pressure, depending on the materials and design.

- Compression Set: Designed to maintain sealing performance over time, resisting deformation under compression.

- Temperature Range

Rubber Metal Gaskets, including edge bonded gaskets, are designed by combining flexible rubber with a strong metal core. This combination helps create a tight, leak-proof seal while maintaining strength and stability. They are widely used in automotive and industrial applications where durability, accurate fit, and resistance to pressure and vibration are essential.

Have some questions?

Frequently Asked Questions (FAQs)

-

What is a Rubber Metal Gasket?

A Rubber Metal Gasket is a sealing part made by combining rubber with a metal base. The rubber creates a tight seal, while the metal gives strength and keeps the gasket stable under pressure.

-

What is an Edge Bonded Gasket?

An Edge Bonded Gasket is a special type of Rubber Metal Gasket where rubber is attached around the edges of a metal core. This helps improve sealing and keeps the gasket properly aligned during installation.

-

Where are Rubber Metal Gaskets used?

These gaskets are commonly used in engines, transmission systems, pumps, compressors, and other industrial machines where strong and reliable sealing is needed.

-

What are the benefits of Edge Bonded Gaskets?

They offer better fit, consistent sealing, and improved resistance to pressure and temperature changes. This reduces the chances of leakage over time.

-

Can these gaskets be customized?

Yes, Rubber Metal Gaskets and Edge Bonded Gaskets can be made according to specific drawings, sizes, and material requirements.

-

How do they improve equipment performance?

The metal keeps the gasket in shape, while the rubber absorbs vibration and seals tightly, helping equipment run smoothly and safely.

-

What materials are used?

They are usually made from rubber compounds bonded to steel or other metals, depending on the working conditions and application needs.