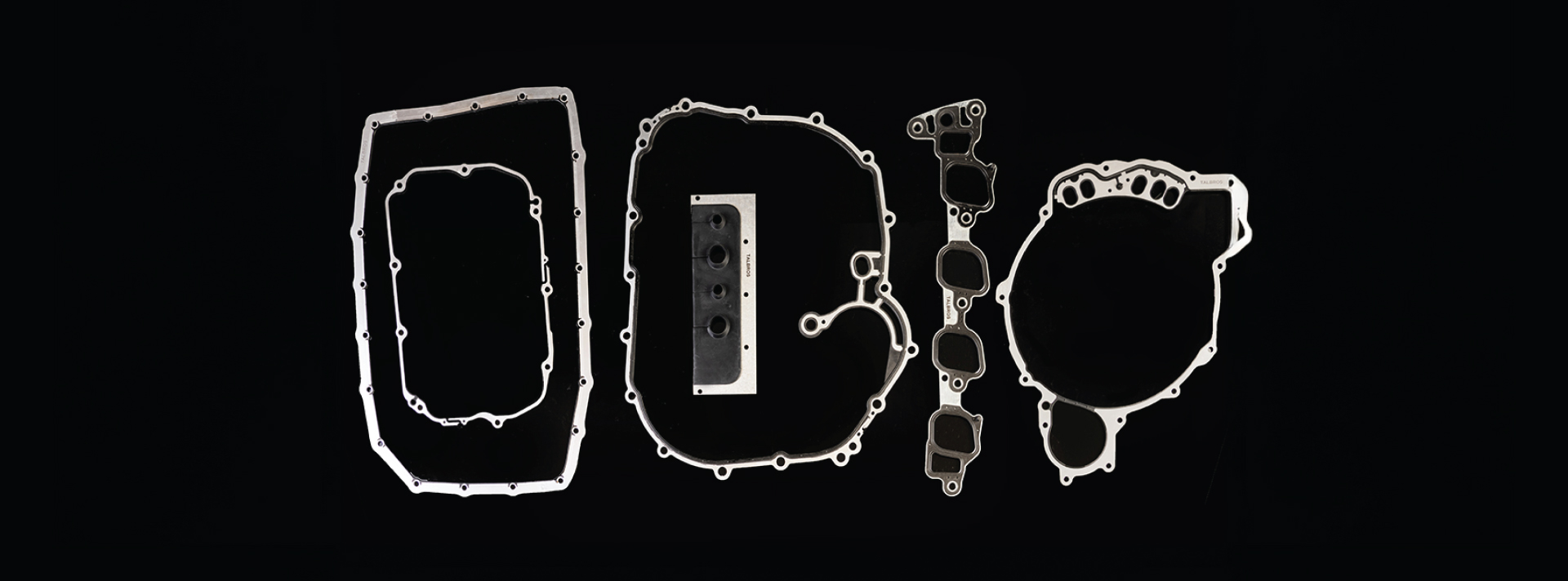

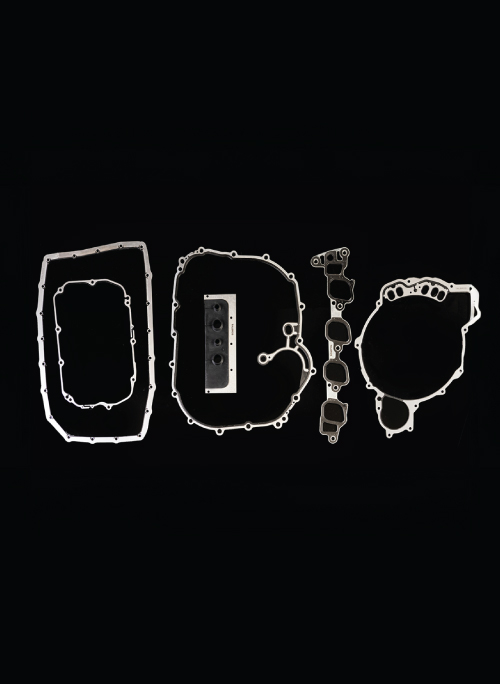

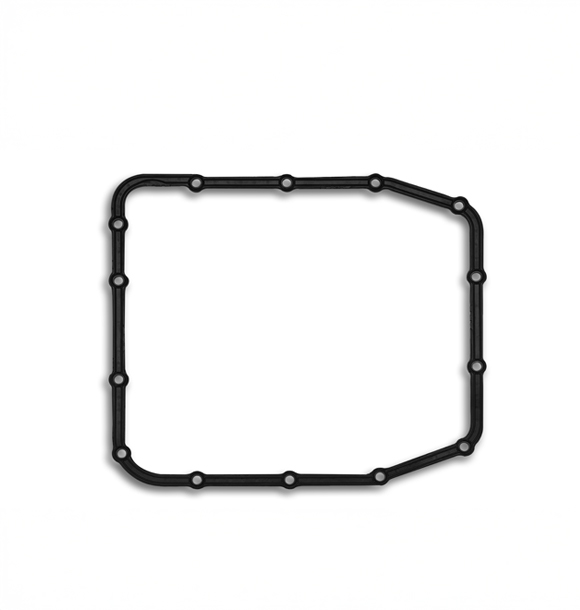

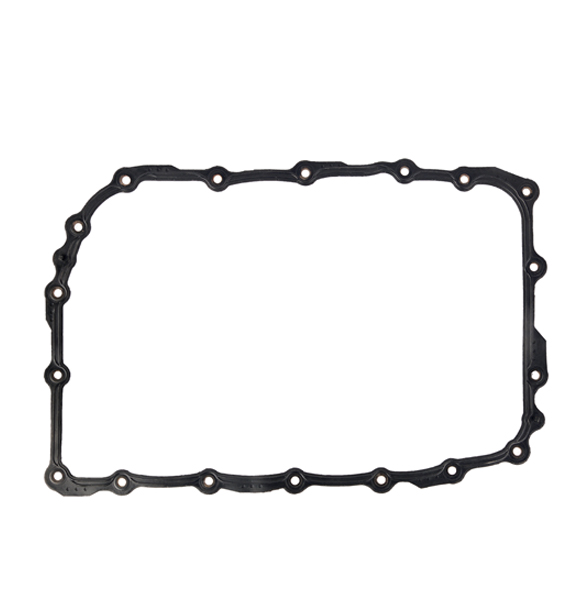

Rubber-Metal Over-molded Gaskets

Rubber-metal over-moulded gaskets are specialized sealing components that combine a metal substrate with a rubber sealing element, created through an over-moulding process. This technique provides a robust, flexible, and durable gasket suitable for various applications. As a trusted manufacturer of rubber metal parts in India, we deliver high-performance solutions designed to meet demanding automotive and industrial requirements.

Composition

- Rubber Component: Typically made from elastomers such as: Nitrile, AEM, HT-ACM, FKM, HNBR and Silicone.

- Metal Substrate: Usually constructed from:

- Steel: Provides strength and durability, suitable for high-pressure applications.

- Aluminium: Lightweight with good corrosion resistance, often used in lower pressure or temperature applications.

Manufacturing Process

- Over-moulding: The rubber is moulded over the pre-fabricated metal component, creating a strong bond between the two materials. This process ensures that the rubber perfectly conforms to the metal, enhancing the sealing capabilities and mechanical properties.

Performance Characteristics

- Temperature Range

- Nitrile: -30°C to +108°C

- EPDM: -40°C to +120°C.

- AEM: -40 C to +175 C

- Fluorocarbon: -20°C to +200°C

- Silicone: -60 C to + 300 C

- Pressure Rating: Typically rated for applications ranging from low to high pressure, depending on the materials and design.

- Compression Set: Designed to maintain sealing performance over time, resisting deformation under compression.

Contact Us

×