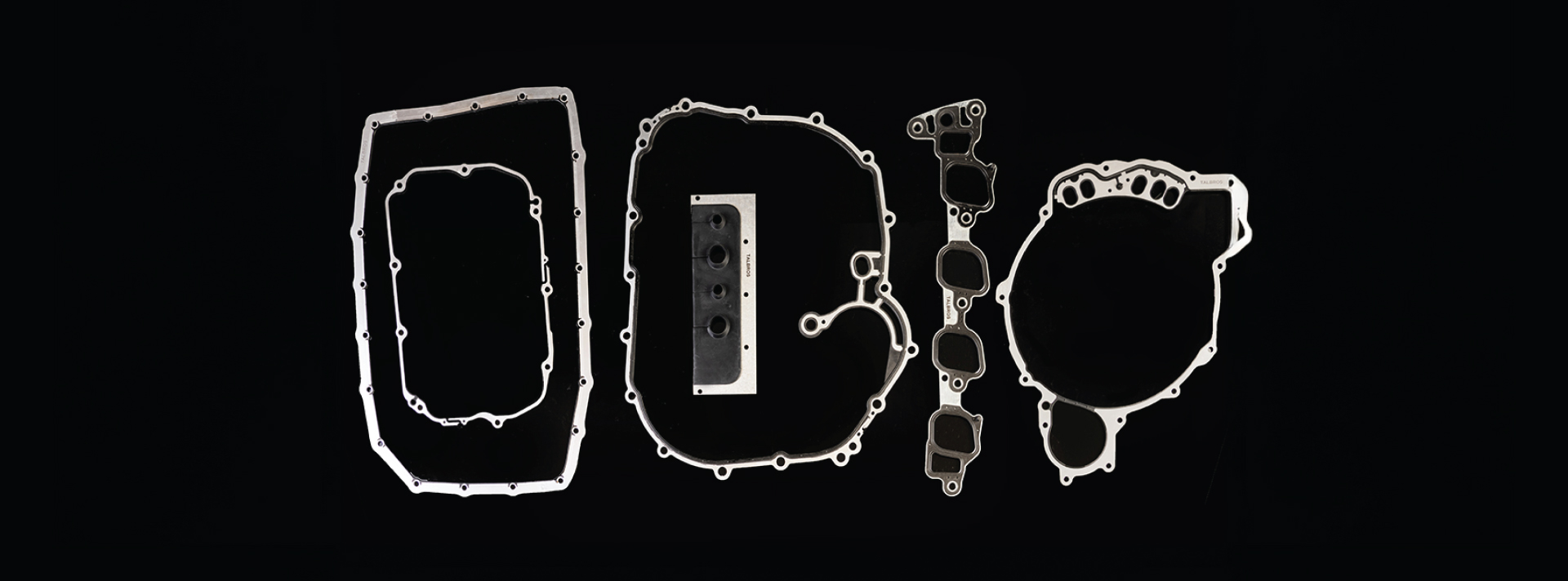

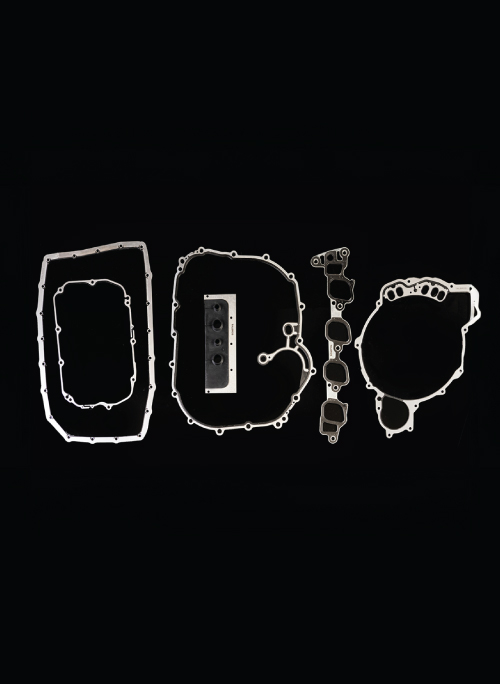

Rubber Coated Steel Gaskets

These gaskets are a high-performance solution designed specifically for applications in demanding industrial, engine, and compressor environments. Combining a robust steel core with a dual-layered rubber coating, this product offers exceptional resilience and sealing properties. Crafted with precision, the gasket material is built to withstand the rigors of high-pressure, high-temperature, and chemically aggressive environments, making it ideal for a wide range of applications.

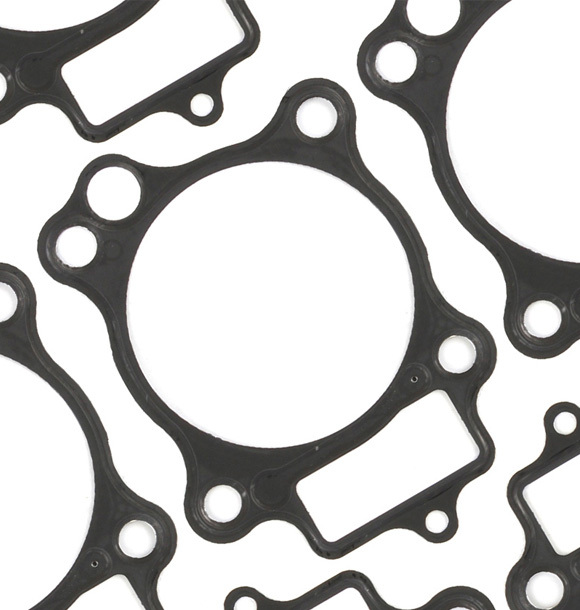

Composition

- Steel Core: The foundation of the gasket is a strong, durable carbon steel core. This provides mechanical strength, ensuring that the gasket can handle significant pressure and mechanical stress without deformation or failure.

- Rubber Coating: The rubber coating offers excellent resistance against mineral and synthetic oils. NBR is known for its durability and flexibility, making it ideal for use in environments where oil resistance and sealing performance are critical.

- Surface Treatment: The gasket features an anti-stick surface treatment, which helps prevent the gasket from adhering to mating surfaces, making it easier to remove and replace when needed without compromising the integrity of the components.

Applications

- Automotive: Engine components, exhaust systems, and other high-temperature applications where reliable sealing is necessary. The NBR coating ensures effective oil and fuel resistance.

- General Industry: For various industrial sealing applications where a combination of mechanical strength and chemical resistance is needed.

- Pumps: Sealing pump systems that are subject to high pressures, temperatures, and exposure to oils or other fluids. The robust nature of the steel core combined with the rubber’s flexibility makes it an ideal choice for pumps.

- Compressors: Ideal for use in compressors, where sealing performance under pressure is critical to prevent leaks and maintain system efficiency.

Contact Us

×