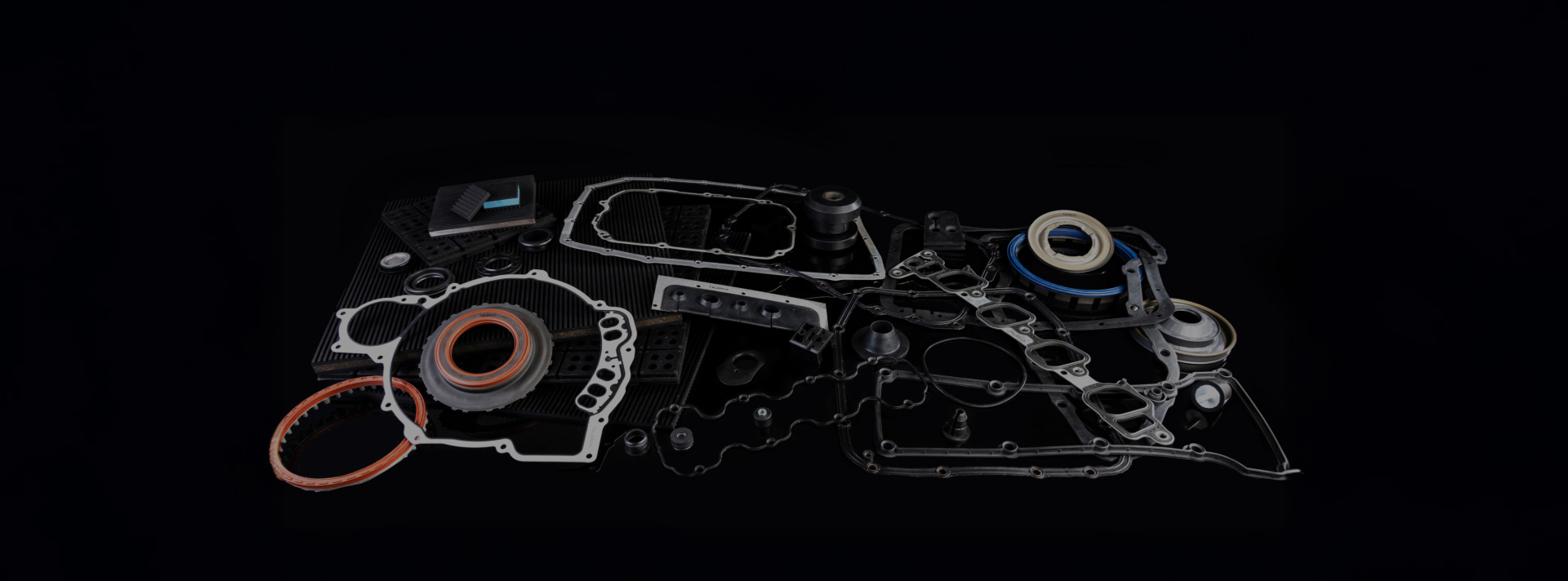

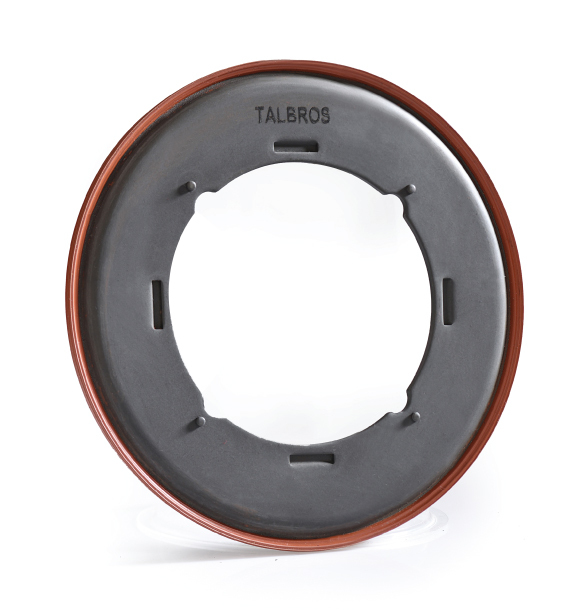

Bonded piston seals

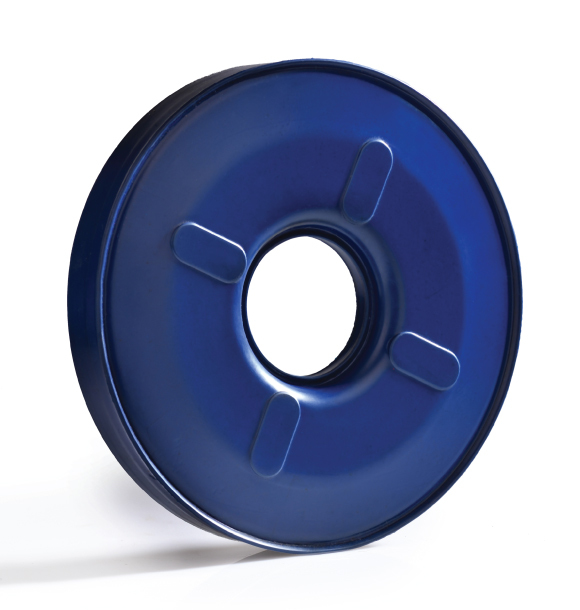

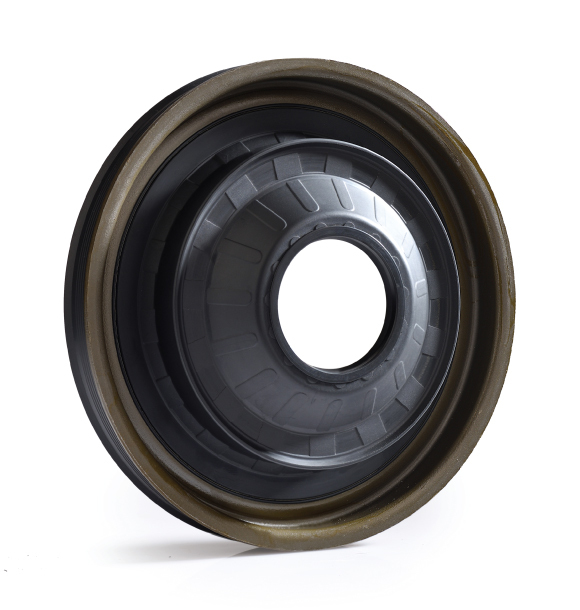

Rubber-metal bonded piston seals are specialized sealing components used in hydraulic and pneumatic systems. They consist of a rubber sealing element bonded to a metal substrate, combining the flexibility and sealing capabilities of rubber with the strength and stability of metal.

Material Composition

1. Rubber Types: Common elastomers used include:

- Nitrile (NBR): Good oil and fuel resistance; suitable for hydraulic applications.

- Ethylene Acrylic (AEM): High resistance to Dex-6 transmission fluid, outstanding heat stability and resistance to motor oil, AFT, ozone and weather.

- Fluorocarbon (FKM): Recommended for applications involving gasoline, ethanol, engine coolant and water up to 200 degrees celcius.

2. Metal Substrate: Typically made from:

- Steel: High strength and durability; often used in high-pressure applications.

- Aluminum: Lightweight with good corrosion resistance; used in lower pressure scenarios.

Performance Characteristics

- Pressure Rating: Typically rated for pressures ranging from 100 to 500 bar (or higher, depending on design and materials).

- Temperature Range:

- Nitrile: -30°C to +100°C

- Polyurethane: -30°C to +80°C (up to +90°C in certain conditions)

- Fluorocarbon: -20°C to +200°C

- Speed Capability: Suitable for dynamic applications with speeds up to 5 m/s, depending on the specific rubber and application

Contact Us

×